Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

The full automatic snack food extruder is a machine used in the food processing industry to produce a variety of snack foods. These extruders are designed to automate the production process, making it more efficient and consistent.

The full automatic snack food extruder is a machine used in the food processing industry to produce a variety of snack foods. These extruders are designed to automate the production process, making it more efficient and consistent. Whether you’re a small snack food manufacturer, a large-scale production facility, or even a home enthusiast looking to create your favorite snacks, this machine offers precision, versatility, and automation to meet your needs.

Full automatic snack food extruders are used to produce a wide range of snack foods, including extruded snacks, puffed snacks, corn curls, rice cakes, and more. They are commonly used in the snack food industry due to their ability to produce large quantities of snacks efficiently and with consistent quality.

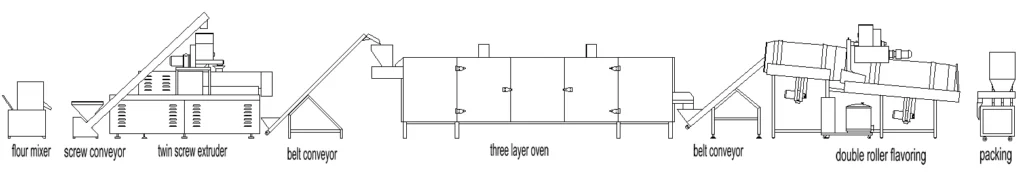

Snack food extruder machine description.

Hopper: The process starts with a hopper where raw ingredients are loaded. This can include ingredients like cornmeal, rice flour, wheat flour, and various flavorings.

Screw Conveyor: A screw conveyor inside the extruder helps transport the ingredients from the hopper into the extrusion chamber.

Extrusion Chamber: This is a crucial component of the extruder. The extrusion chamber typically consists of a barrel and a screw. The ingredients are mixed, heated, and pressurized in this chamber. The heat and pressure cause the ingredients to change their physical and chemical properties.

Die or Nozzle: At the end of the extrusion chamber, there’s a die or nozzle through which the product is forced to shape it into the desired form. This can include shapes like chips, sticks, curls, or other snack food forms.

Cutting Mechanism: A cutting mechanism is used to cut the extruded snack food into the desired lengths. The shape and length can be adjusted based on the die used.

Cooling System: Once the snacks are cut, they need to be cooled to set their structure. This can involve the use of cooling fans or conveyors.

Flavoring and Seasoning: In some machines, there are additional components for flavoring and seasoning the snacks. This can involve the application of oil, salt, or various flavor powders.

Collection and Packaging: After the snacks are extruded, cut, and flavored, they are collected and often transferred to a packaging machine for sealing in bags or containers.

Control System: The extruder is typically controlled by a computerized system that allows operators to adjust various parameters like temperature, pressure, and speed, ensuring consistent product quality.

Snack food extruder machine pictures.

What is the capacity of snack food extruder?

AVN65 extruder has capacity 120-150 kg per hour.

AVN70 extruder has capacity 200-250 kg per hour.

AVN85 extruder has capacity 500-800 kg per hour,

AVN95 extruder has capacity 1000-1200 kg per hour.

The full automatic snack food extruder is a versatile and efficient solution for anyone involved in snack food production. With its automation, flexibility, and production capacity, it enables businesses to produce high-quality snack products to meet the demands of today’s competitive snack food market.