Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

Our extruder machine operates continuously, ensuring a consistent and efficient production process. It can produce a large volume of corn curls without interruption.

Continuous corn curls extruder machine, the ultimate solution for producing delicious and crispy corn curls with ease. This innovative machine is designed to meet the demands of the snack food industry and streamline the production of high-quality corn curls.

Corn Curls Machine Key Features:

Continuous Extrusion: Our extruder machine operates continuously, ensuring a consistent and efficient production process. It can produce a large volume of corn curls without interruption.

Versatile Production: This machine is suitable for a wide range of corn curl products, allowing you to create various shapes and flavors to meet market preferences. Customize your corn curls with ease.

High-Quality Output: The extruder is designed to produce corn curls with a perfect texture, ensuring they are crunchy, tasty, and appealing to consumers. Achieve the quality your customers expect.

Efficiency and Precision: The machine is equipped with advanced controls and automation, allowing you to precisely adjust parameters like temperature, speed, and shape to achieve the desired results consistently.

Easy Maintenance: Designed for user-friendly maintenance, our extruder machine minimizes downtime and ensures long-term reliability. Routine cleaning and upkeep are straightforward.

Safety First: We prioritize safety by incorporating advanced safety features and fail-safes into our machine design, keeping your operators and product quality secure.

Energy-Efficient: Our extruder machine is built with energy-efficient technology to reduce operational costs and minimize environmental impact.

Customization Options: We offer customization options to tailor the machine to your specific production requirements. Whether you need a compact model or an extensive production line, we’ve got you covered.

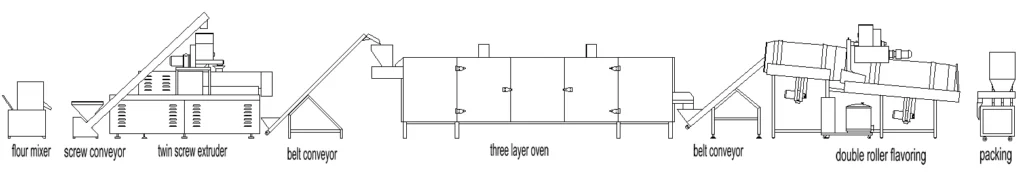

Corn curls machine flow chart.

Mixer machine—-conveyor machine—extruder machine—conveyor machine—dryer machine—flavoring machine—packing machine

Corn Curls Machine Applications:

Curls Snacks Machine Technical Specifications:

Invest in our Continuous Corn Curls Machine to elevate your snack production to new heights. With its efficiency, precision, and versatility, you can meet market demands, reduce production costs, and maintain a competitive edge in the snack food industry. Contact us today to discuss your specific requirements and discover how our extruder machine can transform your production process.

The corn curls machine capacity.

AVN65 Machine line has capacity 120-150 kg per hour.

AVN70 Machine line has capacity 200-250 kg per hour.

AVN85 Machine line has capacity 500-800 kg per hour,

AVN95 Machine line has capacity 1000-1200 kg per hour.