Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

The snack food extruder machine, often simply referred to as an extruder, is a piece of food processing equipment used to produce a wide variety of snack foods. These machines are commonly used in the food industry to create products such as puffed snacks, cereal products, and pet food and so on.

The snack food extruder machine, often simply referred to as an extruder, is a piece of food processing equipment used to produce a wide variety of snack foods. These machines are commonly used in the food industry to create products such as puffed snacks, cereal products, and pet food and so on.

.

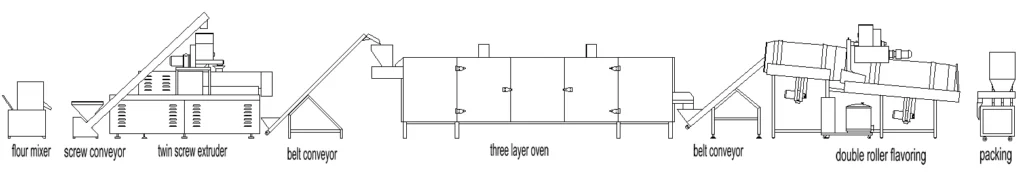

Here’s how a snack food extruder machine typically works:

Ingredient Mixing: The process starts by mixing various ingredients like grains, starches, flavorings, and water to create a dough or a mixture with a specific texture and consistency.

Feeding the Extruder: The prepared mixture is fed into the extruder machine through a hopper or feeder.

Extrusion: The heart of the machine is the extrusion chamber, which consists of a barrel with a screw inside. The screw rotates and pushes the mixture through the barrel.

Pressure and Temperature: Inside the barrel, the mixture is subjected to high pressure and temperature. This combination of pressure, heat, and mechanical action causes the mixture to cook and expand. The pressure is created as the mixture is forced through a die (a specially shaped opening) at the end of the barrel.

Expansion: As the mixture exits the die, it rapidly expands due to the sudden release of pressure. This expansion is what gives the snacks their characteristic puffed texture.

Cutting and Shaping: The extruded product is cut into the desired shapes and sizes by using blades or cutters integrated into the machine.

Cooling: Some snacks may be subjected to a cooling process to bring down their temperature.

Flavoring and Seasoning: After the cooling step, the snacks are often flavored or seasoned with various coatings or powders. This can be done in a separate machine or as part of the extruder.

Packaging: The final products are then typically packaged for distribution and sale.

What is the capacity of snack food extruder machine?

AVN65 extruder has capacity 120-150 kg per hour.

AVN70 extruder has capacity 200-250 kg per hour.

AVN85 extruder has capacity 500-800 kg per hour,

AVN95 extruder has capacity 1000-1200 kg per hour.

Snack food extruder machines come in various sizes and designs, depending on the specific type of snack being produced. Different extruder configurations and die designs can create various shapes, from simple sticks to complex three-dimensional forms. The versatility of these machines makes them a key component in the production of many popular snack foods.

Some examples of snack products made with extruders include cheese puffs, corn curls, rice cakes, breakfast cereals, and more. These machines are critical in large-scale snack production due to their efficiency and ability to produce consistent, high-quality products.