Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

This machine line includes automatic mixing, kneading, extruding, and cutting of the pasta. Automation can significantly increase efficiency and reduce the need for manual intervention.

Automatic electric pasta machines are devices designed to simplify and automate the process of making pasta. These machines are commonly used in commercial pasta factory to streamline the pasta-making process.

Here are some features and aspects to consider when looking at an automatic electric pasta machine for industrial use:

Production Capacity:

Industrial machines should have a high production capacity to meet the demands of a commercial setting. Look for machines that can produce a large quantity of pasta per hour.

Material and Construction:

Consider the materials used in the construction of the machine. Stainless steel is a common choice for its durability and ease of cleaning, which is important in a commercial food factory.

Automation Features:

This machine line includes automatic mixing, kneading, extruding, and cutting of the pasta. Automation can significantly increase efficiency and reduce the need for manual intervention.

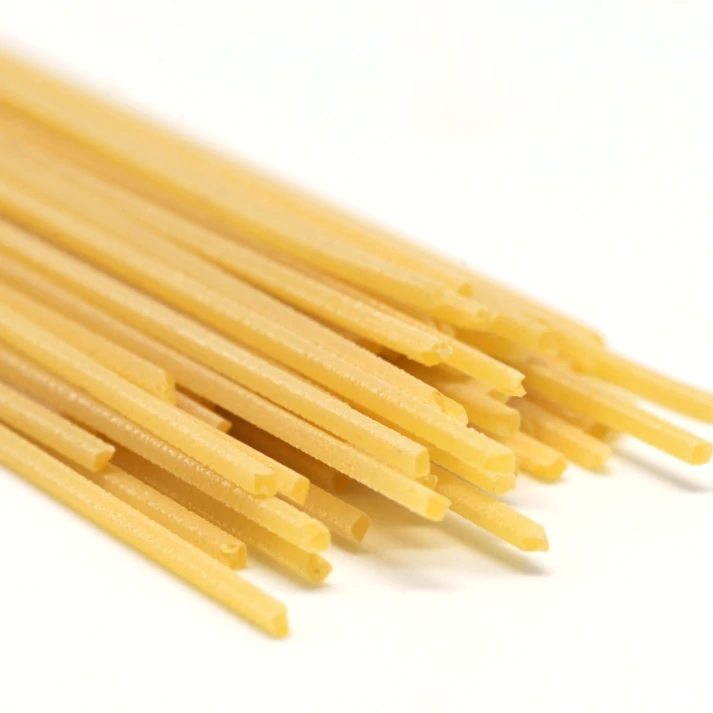

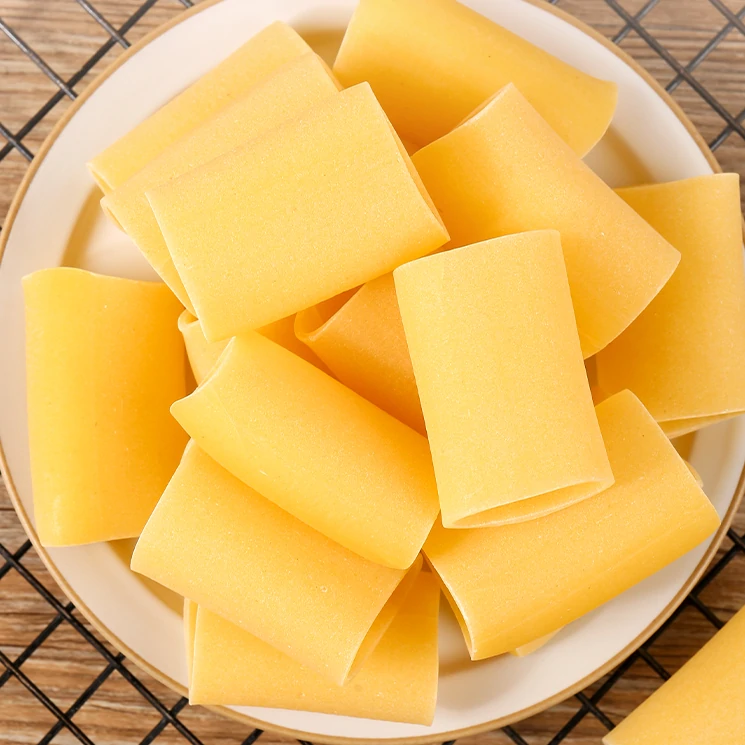

Versatility:

Choose a machine that can produce a variety of pasta shapes and sizes. This versatility is crucial for meeting diverse customer preferences.

Ease of Cleaning:

Industrial factory equipment is easy to clean to maintain hygiene standards. Look for machines with detachable parts that are dishwasher safe or can be easily cleaned by hand.

Power and Speed:

The power and speed of the machine. A powerful motor and high-speed operation can contribute to faster pasta production.

Safety Features:

Ensure the machine has safety features, such as emergency stop buttons and protective covers, to prevent accidents in a busy working environment.

Brand Reputation and Reviews:

Research the reputation of the brand and read reviews from other users to ensure that the machine is reliable and performs well under industrial conditions.

Customization Options:

Some machines allow for customization of pasta recipes, allowing you to adjust ingredients and create unique pasta varieties. This can be a valuable feature for businesses looking to offer specialty pasta products.

Warranty and Support:

Check the warranty offered by the manufacturer and the availability of customer support. A good warranty and reliable customer support can be essential for addressing any issues that may arise.

Automatic electric pasta machine capacity.

|

Item |

AVN50 |

AVN100 |

AVN200 |

AVN300 |

|

Capacity |

50 kg/h |

100 kg/h |

200kg/h |

300kg/h |

When choosing an automatic electric pasta machine for an industrial setting, it’s important to carefully assess your specific needs and the features of the machine to ensure it aligns with your production requirements.

Welcome your inquiry on automatic electric pasta machine.