Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

The extrusion process forms the corn mixture into the iconic flake shape, followed by cooking to achieve the desired texture and taste.

The Corn Flakes Production Machine is an advanced and efficient industrial equipment designed for the automated manufacturing of high-quality corn flakes, a popular breakfast cereal loved by people of all ages. This state-of-the-art machine streamlines the entire production process, from raw material preparation to packaging, ensuring consistency in product quality and substantial cost savings for manufacturers.

Corn Flakes Production Machine Key Features and Benefits:

1.Material Handling: The machine is equipped to handle a variety of corn-based ingredients, from corn grits to corn flour, ensuring flexibility in production.

2.Precise Mixing: It features a precision mixing system that blends the corn ingredients with water and other additives to create a homogeneous mixture, which is crucial for the quality of the final product.

3.. Extrusion and Cooking: The extrusion process forms the corn mixture into the iconic flake shape, followed by cooking to achieve the desired texture and taste.

4. Flake Formation: The extruded product is flattened and cut into flakes of uniform size and thickness.

5. Drying: A controlled drying system removes excess moisture, enhancing the shelf life of the corn flakes and preventing them from becoming soggy.

6. Toasting: The machine can also be equipped with toasting capabilities, allowing for the production of toasted corn flakes with a golden, crispy texture.

7. Quality Control: Integrated quality control mechanisms ensure consistent product quality and minimize waste.

8. Easy Maintenance: Designed for user-friendliness and low maintenance requirements, reducing downtime and operational costs.

9. Customization: Manufacturers can tailor the machine’s settings to produce different flavors, shapes, and sizes of corn flakes to meet consumer demands.

10.Output Capacity: The machine comes in various models with different production capacities to suit the needs of both small-scale and large-scale cereal production.

11.Packaging: It can be integrated with packaging systems for convenient and hygienic packaging of corn flakes in various formats, such as bags, boxes, or containers.

12.Energy Efficiency: The machine is designed to be energy-efficient, helping manufacturers reduce operational costs and environmental impact.

Corn flakes production machine technology.

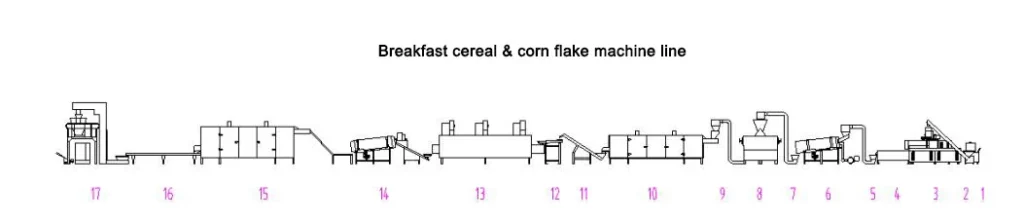

Corn flakes production machine flow chart.

Mixer machine—conveyor machine—extruder machine—dryer machine—suger sprayer machine—dryer machine—cooling machine.

The Corn Flakes Production Machine is an indispensable asset for cereal manufacturers, providing a cost-effective and consistent solution for producing high-quality corn flakes that meet the demands of the market. Whether you are starting a new cereal production line or upgrading an existing one, this machine offers the technology and efficiency required to stay competitive in the breakfast cereal industry.

Corn flakes production machine capacity.

AVN65 machine line has capacity 120-150 kg per hour.

AVN70 machine line has capacity 200-250 kg per hour.

AVN85 machine line has capacity 400-500 kg per hour.

Welcome your inquiry on corn flakes production machine.