Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

Function: Corn flakes manufacturing.

Capacity:120kg/hour, 200kg/hour, 500kg/hour,

Model: AVN65, AVN70, AVN85

Category: Corn Flakes Processing Line

Brand: AVAN MACHINERY

Price: USD9000 to USD25000 PER SET.

Supply Ability: 5 SETS PER MONTHLY

Are you looking to start or expand your corn flakes manufacturing business? Our state-of-the-art Corn Flakes Manufacturer Equipment is designed to meet your production needs efficiently and effectively. Crafted with precision and advanced technology, our equipment ensures the production of high-quality corn flakes that are not only delicious but also nutritious.

Corn Flakes Manufacturer Equipment Key Features:

High Production Capacity: Our equipment is engineered to deliver high production output, allowing you to meet the demands of a growing market.

Versatility: It can be used to produce a variety of corn flakes, including plain, honey-glazed, or flavored corn flakes, offering flexibility to cater to different consumer preferences.

Quality Assurance: The equipment is built to maintain product consistency and quality throughout the manufacturing process, ensuring that your corn flakes meet the highest industry standards.

Energy Efficiency: We prioritize energy efficiency, which reduces operating costs and minimizes your carbon footprint.

User-Friendly: Our equipment is designed with user-friendliness in mind, making it easy to operate and maintain, with minimal training required.

Robust Construction: Built to withstand the rigors of continuous production, our equipment is durable and designed to have a long operational life.

Advanced Automation: Our equipment features cutting-edge automation systems, ensuring precise control over the production process and reducing the risk of human error.

Sanitary Design: Hygiene is a top priority. Our equipment is designed for easy cleaning and maintenance to meet strict food safety standards.

Customization Options: We offer customization to tailor the equipment to your specific requirements, including capacity, packaging, and other features.

Expert Support: Our team of experts provides comprehensive support, including installation, training, and ongoing maintenance to ensure your business runs smoothly.

Cost-Effective: Investing in our Corn Flakes Manufacturer Equipment means a cost-effective solution that will help you achieve your business goals.

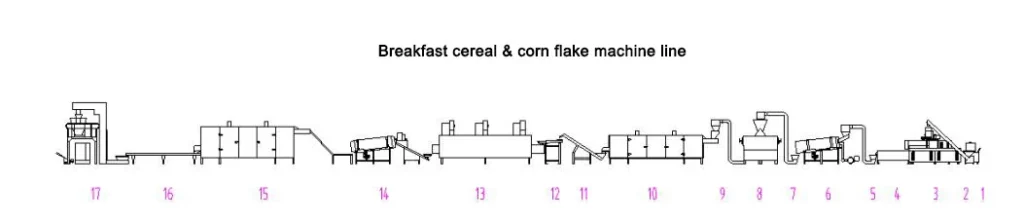

Corn flakes manufacturer equipment flow chart.

Mixer machine—conveyor machine—extruder machine—Vibrate cooler—dum cooling machine—flake presser machine—dryer machine—vibrate distributor machine—Baking machine—suger sprayer machine—dryer machine—cooling machine.

Whether you are a well-established corn flakes producer looking to upgrade your equipment or a newcomer to the industry, our Corn Flakes Manufacturer Equipment is a reliable choice to enhance your production capabilities and meet the growing demand for delicious and nutritious corn flakes. Contact us today to discuss your specific needs and learn how our equipment can help you succeed in the corn flakes manufacturing business.

Corn flakes manufacturer equipment capacity.

AVN65 machine line has capacity 120-150 kg per hour.

AVN70 machine line has capacity 200-250 kg per hour.

AVN85 machine line has capacity 400-500 kg per hour.

Extrusion Machine Line Advantage:

1.Feeding System: Raw materials are fed into the extruder through a feeding system. This system includes hoppers, feeders, and conveyors to ensure a steady supply of ingredients to the extruder.

2.Extruder: The heart of the system is the extruder, which is responsible for the cooking and shaping of the snack. It usually consists of a barrel, screws, and a die. The raw ingredients, such as grains or starches, are fed into the extruder where they are cooked, pressurized, and pushed through a die to give the snack its final shape.

3.Cutting System: Once the extruded snack has been formed, a cutting system is used to cut it into the desired shape and size. This can include rotary cutting systems, knives, or other cutting mechanisms depending on the specific snack being produced.

4.Drying Chamber Design: The design of the drying chamber is important for efficient moisture removal. It should allow for even airflow around the snacks to ensure uniform drying.

5.Cooling System: After the snacks are dryed, they may pass through a cooling system to bring down the temperature and set the final texture. This helps in the solidification of the product and ensures it is ready for packaging.

6.Flavoring and Seasoning System: Many extrusion snacks machines have a system for applying flavors and seasonings to the finished snacks. This can be done through a drum coating system or other methods to ensure an even distribution of flavors.

7.Conveyor System: A conveyor system is used to transport the snacks from one part of the machine to another. This is essential for maintaining a continuous and efficient production process.

8.Control Panel: Modern extrusion snacks machines come with a user-friendly control panel. This panel allows operators to monitor and control various parameters such as temperature, pressure, and speed. It ensures precise control over the extrusion process, leading to consistent product quality.

9.Safety Features: Extrusion snacks machine lines are equipped with safety features to protect operators and prevent accidents. Emergency stop buttons, safety interlocks, and protective covers are commonly incorporated.

10.Hygienic Design: The equipment is often designed to meet strict hygiene standards in the food industry. This includes easy-to-clean surfaces, sanitary construction materials, and accessibility for cleaning and maintenance.

11.Capacity and Flexibility: Extrusion snacks machine lines come in various sizes and capacities to meet the production needs of different manufacturers. Some machines also offer flexibility in terms of producing different types of snacks by adjusting parameters.

12.Energy Efficiency: Manufacturers often design these machines with energy-efficient features to reduce operational costs and environmental impact.

Details Picture of Machines

Customer & Service

We shipped the machinery to numerous countries globally, including Italy, Germany, Russia, Turkey, Australia, Indonesia, India, etc. Our machines and service have received commendations from nearly every customer, fostering repeat business.

1.Twelve months following installation (Within 13 months of delivery).

2.Complimentary advisory service prior to, during, and post-sales.

3.Supply fundamental production methods and formulations.

4.International on-site setup and personalized training for machine maintenance and operation.

5.Calibration and examination of the machinery until all components are operational before departing the manufacturing facility.

Packaging & Shipping

1.Daub coal oil on the surface of the machines.

2.Plastic film as the inner packing.

3.Train, ship of depend on clients’ requirement.

FAQ

Q: What is the duration of your warranty period?

A: Our guarantee spans one year from the commencement of operations.

Q: Can you describe the installation process?

A: We will deploy our skilled technicians to your facility to oversee the installation and commissioning tasks, providing training for your operators.

Q: If we share our factory layout, can you assist in designing the entire production line?

A: Certainly, our seasoned engineers and technical staff can aid in organizing the layout and overseeing the installation of the entire production line, tailored to your specific circumstances.

Q: What is the timeframe for your delivery?

A: Typically, it takes 7 – 10 days for stocked items, and 20 – 25 days for non-stock items, depending on the quantity.

Q: Will you provide support if issues arise during future production?

A: Absolutely, we are committed to being at your service. You can reach me through mobile, WhatsApp, Skype, Viber, WeChat, and more. I will promptly address and resolve any problems you encounter.

If you’re looking to meet the growing demand for delicious corn flakes and diversify your product offerings, the corn flakes making machine is an excellent choice. It combines efficiency, versatility, and quality to help you create the perfect puff corn treats for your customers, setting your business apart in the snack industry.

Welcome your inquiry on corn flakes manufacturer equipment.