Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

The corn flake machine utilizes advanced extrusion technology to cook and shape the corn dough into the characteristic flat and flaky corn flakes. This process ensures uniform texture and consistent quality.

The Corn Flakes Processing Machine is a highly specialized and efficient piece of equipment designed for the production of delicious and crispy corn flakes. It is an essential tool for manufacturers in the cereal and snack food industry. This machine is engineered to transform raw corn grits or maize into the popular breakfast cereal known as corn flakes, which are loved by people of all ages.

The corn flakes processing machine technology.

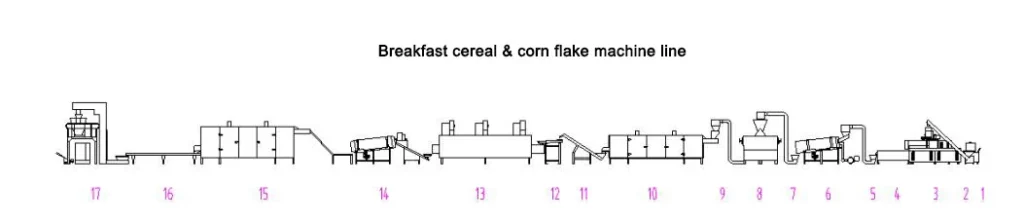

Corn flakes processing machine flow chart.

Mixer machine—conveyor machine—extruder machine—dryer machine—suger sprayer machine—dryer machine—cooling machine.

Corn Flakes Processing Machine Key Features and Benefits:

Extrusion Technology: The machine utilizes advanced extrusion technology to cook and shape the corn dough into the characteristic flat and flaky corn flakes. This process ensures uniform texture and consistent quality.

High Productivity: The Corn Flakes Extrusion Processing Machine offers high production capacity, allowing manufacturers to meet the demands of a growing market efficiently.

Versatile Applications: It can be used for producing various shapes and flavors of corn flakes, catering to diverse consumer preferences.

Precise Control: The machine offers precise control over parameters like temperature, moisture content, and cutting speed, enabling the production of corn flakes with specific attributes.

Energy Efficiency: Designed with energy-saving features to minimize operational costs and reduce environmental impact.

Easy Maintenance: The equipment is designed for easy cleaning and maintenance, ensuring minimal downtime and efficient operation.

Food Safety: Manufactured using food-grade materials and adhering to strict hygiene standards, the machine produces safe and high-quality corn flakes.

Customization: Depending on the specific production requirements of the customer, the machine can be customized to meet their needs.

Compact Design: The compact design of the machine saves valuable floor space in the production facility.

User-Friendly Interface: Equipped with a user-friendly control panel, the machine is easy to operate, and it can be configured to produce various sizes and shapes of corn flakes.

The Corn Flakes Processing Machine is an indispensable tool for businesses looking to produce consistent and high-quality corn flakes for the breakfast cereal market. It combines efficiency, versatility, and ease of use, making it an excellent investment for food manufacturers.

Corn Flakes Processing Machine Capacity.

AVN65 machine line has capacity 120-150 kg per hour.

AVN70 machine line has capacity 200-250 kg per hour.

AVN85 machine line has capacity 400-500 kg per hour.

Welcome your inquiry on corn flakes processing machine.