Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

This Corn Flakes machine utilize advanced extrusion technology, the system can efficiently cook and shape corn masa into the desired flake shapes, ensuring consistent texture and taste.

The Corn Flakes Production Line is a good manufacturing system designed for the efficient and automated production of high-quality corn flakes, a popular breakfast cereal enjoyed by people worldwide. This production line is engineered to meet the demands of modern food processing, ensuring consistent product quality, cost-effectiveness, and versatility.

The corn flakes production line technology.

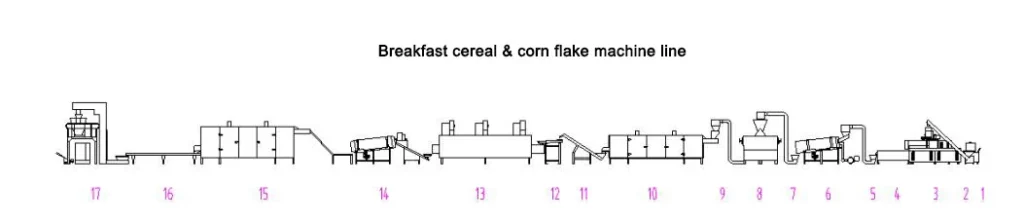

Breakfast cereals production line flow chart.

Mixer machine—conveyor machine—extruder machine—dryer machine—suger sprayer machine—dryer machine—cooling machine.

Corn flakes production line flow chart.

Mixer machine—conveyor machine—extruder machine—Vibrate cooler—dum cooling machine—flake presser machine—dryer machine—vibrate distributor machine—Baking machine—suger sprayer machine—dryer machine—cooling machine.

Mixer machine. There are multiple materials and water in the formula, mixer machine will mix them together.

Conveyor machine. It is a transport conveyor on raw materails.

Extruder machine. Mainly machine to make the half cooked corn flake balls.

Vibrate cooling. Avoid the stick of all balls.

Drum cooling. Cool down the temperature of the corn flake ball.

Corn flake press machine. Press the corn flake ball into the cornflakes pieces.

Dryer machine. Dry the cornflakes to the right moisture content.

Baking machine. Cook the flakes, and make the cornflake crispy.

Sugar sprayer machine.

Dryer machine. Dry the liquid suger.

Cooling machine.

Packing machine.

Corn Flakes Production Line Key Features:

1.High Capacity: The production line is capable of processing large quantities of corn to meet the demands of both small and large-scale cereal manufacturers.

2.Extrusion Technology: Utilizing advanced extrusion technology, the system can efficiently cook and shape corn masa into the desired flake shapes, ensuring consistent texture and taste.

3.Automated Operation: The entire production process, from raw material handling to packaging, is automated, reducing labor requirements and enhancing efficiency.

4.Versatility: The production line is adaptable to produce a variety of corn flake products, including plain corn flakes, honey-flavored corn flakes, and more. This versatility allows manufacturers to cater to different consumer preferences.

5.Precise Temperature and Moisture Control: The system features precise temperature and moisture control to maintain product quality and consistency.

6.Energy Efficiency: Designed with energy-saving features, the production line minimizes energy consumption while maximizing production output.

7.Easy Maintenance: The design includes user-friendly components and quick-change parts, making maintenance and cleaning straightforward.

8.Quality Assurance: The production line incorporates quality control mechanisms to ensure that every corn flake meets the desired standards for taste, texture, and appearance.

9.Optional Flavoring System: An optional flavoring system can be integrated into the production line to apply seasonings and coatings, enhancing the variety of products offered.

10.Packaging Solutions: The production line can be configured with packaging equipment for various packaging options, including bags, boxes, or other customer-specific packaging.

Corn Flakes Machine Applications:

The Corn Flakes Production Line is ideal for food manufacturers, cereal producers, and snack food companies looking to produce high-quality corn flakes efficiently and at scale. The production line can cater to a wide range of customer preferences and market demands.

Overall, this production line represents a turnkey solution for the efficient and cost-effective production of delicious corn flakes, meeting the high standards of quality and consistency that consumers expect.

Corn flakes production line capacity.

AVN65 machine line has capacity 120-150 kg per hour.

AVN70 machine line has capacity 200-250 kg per hour.

AVN85 machine line has capacity 400-500 kg per hour.

Welcome your inquiry on corn flakes production line.