Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

The cat food machine is a piece of equipment used in the pet food manufacturing industry to produce cat food products. Extrusion is a common processing method for manufacturing various types of pet foods, including dry kibble and some types of treats. This machine is designed to take raw ingredients and transform them into a finished cat food product with a specific shape, texture, and nutritional profile.

The cat food machine is a piece of equipment used in the pet food manufacturing industry to produce cat food products. Extrusion is a common processing method for manufacturing various types of pet foods, including dry kibble and some types of treats. This machine is designed to take raw ingredients and transform them into a finished cat food product with a specific shape, texture, and nutritional profile.

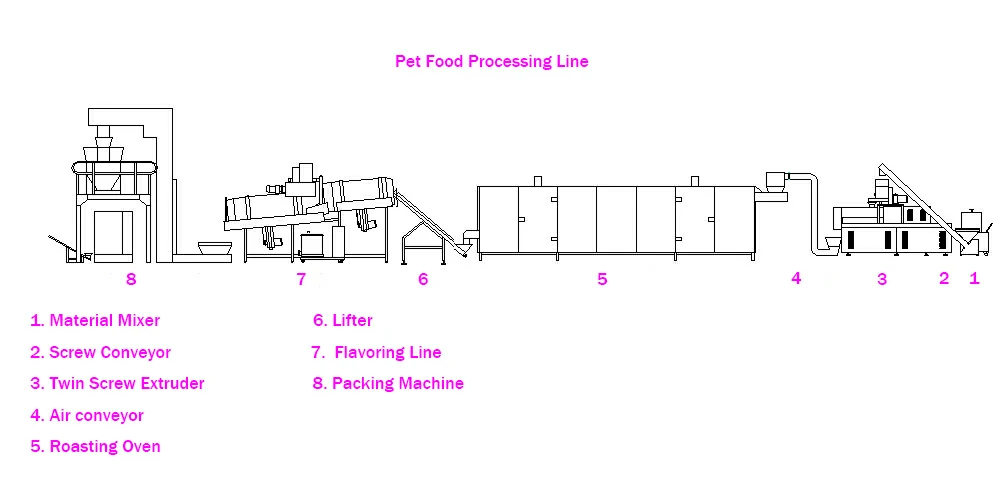

The cat food machine typically works:

Mixing: Raw ingredients such as meat, grains, vegetables, and additives are thoroughly mixed to create a homogenous blend. This mixture is often referred to as a “dry mix.”

Conditioning: The dry mix is then preconditioned with steam and water to achieve the desired moisture content and temperature. This step is crucial for the extrusion process.

Extrusion: The conditioned mixture is fed into the extrusion machine, which consists of a barrel and a screw. Inside the barrel, the mixture is subjected to heat, pressure, and mechanical force. As it moves through the barrel, it undergoes cooking and shearing, which transforms the mixture into a dough-like consistency.

Shaping: At the end of the extruder barrel, the dough is forced through a shaping die with specific openings or cutters. This die determines the shape and size of the final cat food product. For example, it can produce kibble shapes or other forms commonly found in cat food.

Cutting: The extruded product is then cut to the desired length to create individual pieces, such as kibble.

Drying and cooling: The newly formed cat food pieces are typically dried and cooled to reduce moisture content and ensure stability for storage.

Coating and flavoring: After extrusion and drying, some cat foods may be coated with flavorings, vitamins, or other additives to enhance taste and nutritional value.

Packaging: The finished cat food products are packaged into bags or containers for distribution and sale.

Cat food machines are essential for large-scale cat food production because they allow for precise control over the product’s ingredients, shape, size, and texture. This enables pet food manufacturers to produce consistent and high-quality cat food products that meet the nutritional needs of cats.

Cat food machine capacity.

AVN65 extruder machine has capacity 120-150 kg per hour.

AVN70 extruder machine has capacity 200-250 kg per hour.

AVN85 extruder machine has capacity 500-800 kg per hour.

AVN95 extruder machine has capacity 1000-1200 kg per hour.

Welcome your inquiry on cat food machine.

Cat food machine working video showing.