Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

The extrusion cat food production line is a manufacturing process used to produce cat food, particularly dry kibble. Extrusion is a common method in the pet food industry for creating dry pet food due to its efficiency and ability to produce a wide variety of shapes, sizes, and formulations of cat food.

The extrusion cat food production line is a manufacturing process used to produce cat food, particularly dry kibble. Extrusion is a common method in the pet food industry for creating dry pet food due to its efficiency and ability to produce a wide variety of shapes, sizes, and formulations of cat food.

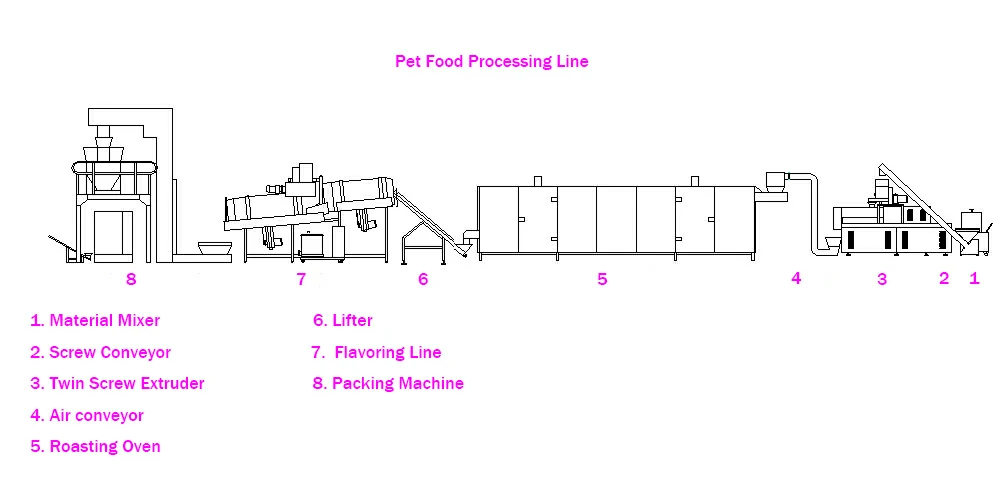

The cat food production line process involves several key steps:

Mixing: Ingredients such as meat meal, grains, vitamins, minerals, and other additives are thoroughly mixed to create a uniform blend. This mixture is known as the “dough.”

Conditioning: The dough is then heated and conditioned to achieve the right moisture content and temperature for extrusion. This step helps make the mixture more pliable and easier to process.

Extrusion: The conditioned dough is forced through an extruder machine. This machine typically consists of a screw or auger that rotates within a barrel. The combination of heat, pressure, and shear forces within the extruder cooks the ingredients and shapes the cat food into the desired form, usually small kibbles.

Cutting and shaping: As the cat food mixture exits the extruder, it is cut into the desired shapes by a cutting mechanism. The shape, size, and texture of the cat food can be adjusted by changing the extrusion die and cutter configurations.

Drying: The newly formed cat food pieces are then dried to reduce their moisture content to the desired level, usually around 10% to 12%, which helps preserve the food and extend its shelf life.

Coating and flavoring: After drying, the cat food may undergo a coating process to add fats, flavors, and other nutrients to enhance its taste and nutritional value.

Cooling and packaging: The finished cat food is cooled and then packaged for distribution and sale.

AVN65 cat food production line has capacity 120 kg per hour.

AVN70 cat food production line has capacity 200 kg per hour.

AVN85 cat food production line has capacity 500-800 kg per hour.

AVN95 cat food production line has capacity 1000-1200 kg per hour.

Extrusion is favored in the pet food industry because it can effectively process a wide range of ingredients, including meat, grains, vegetables, and additives, ensuring that the final product meets the nutritional requirements for cats. Additionally, it can create different shapes, textures, and formulations to cater to various cat food preferences and dietary needs.

Welcome your letter to get more cat food production line information.