Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

Corn chips machine, also known as a corn chips production line or corn chips making machine, is a piece of equipment used to manufacture corn chips, which are a popular snack made from corn materials. These machines are typically used in the food processing industry to produce large quantities of corn chips efficiently and consistently.

Corn chips machine, also known as a corn chips production line or corn chips making machine, is a piece of equipment used to manufacture corn chips, which are a popular snack made from corn materials. These machines are typically used in the food processing industry to produce large quantities of corn chips efficiently and consistently.

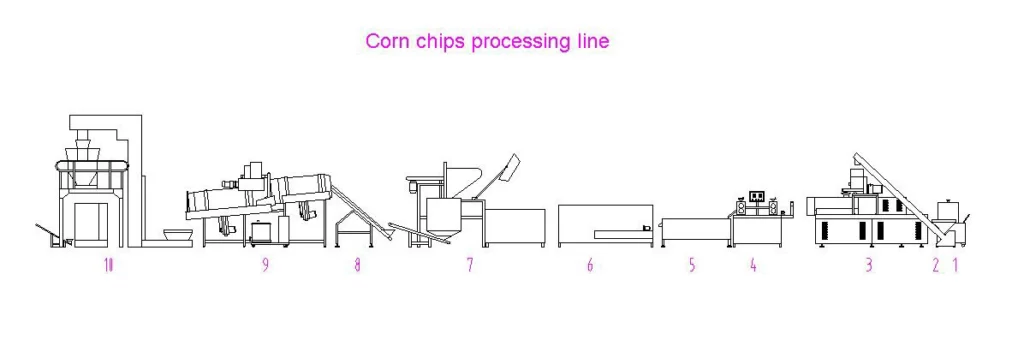

The components and processes typically found in a corn chips machine:

1. Mixer: This is where corn flour or masa is mixed with water and other ingredients.

2. Extruder: The mixed material is then fed into an extruder, which shapes the corn materials into the desired corn chip form, often triangles or rectangles. The extruder pushes the corn materials through a die to achieve the specific shape.

3. Cutting and Shaping: The extruded dough is cut into individual chip-sized pieces. The cutting process may involve rotary cutters or other cutting mechanisms, depending on the design of the machine.

4. Frying or Baking Section: The cut corn chips are then subjected to either frying in hot oil or baking in an oven. Frying typically imparts a crispy texture and flavor to the chips, while baking is a healthier alternative.

5. Seasoning: After frying or baking, the corn chips may pass through a seasoning drum or conveyor where they are coated with various flavors and seasonings. Common seasonings include salt, spices, cheese powder, and more.

6. Cooling Conveyor: The freshly cooked and seasoned corn chips are cooled on a conveyor belt to bring them to room temperature before packaging.

7. Packaging: Once cooled, the corn chips are typically packaged in bags or containers, ready for distribution to consumers.

Corn chips machines come in various sizes and configurations, from small-scale machines suitable for small snack businesses to large industrial production lines used by major snack food manufacturers. These machines are designed to streamline the production process, ensure consistency in chip size and quality, and increase production efficiency. The choice of machine and production methods (frying vs. baking) may vary depending on the specific requirements of the manufacturer and the desired end product.

The corn chips machine capacity.

| Item | AVN65 | AVN70 | AVN85 | AVN90 |

| Capacity | 120-150 kg/hour | 200-250 kg/hour | 500-800 kg/hour | 1000-1200 kg/hour |

Welcome your inquiry, if you have interest in corn chips machine.