Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

Function: Corn chips snacks processing machine line.

Capacity:120kg/hour, 200kg/hour, 500kg/hour,

Model: AVN65, AVN70, AVN85

Category: Corn chips snacks extrusion machine

Brand: AVAN MACHINERY

Price: USD9000 to USD25000 PER SET.

Supply Ability: 5 SETS PER MONTHLY

Payment Method: T/T,L/C, Western Union, Money Gram, Paypal.

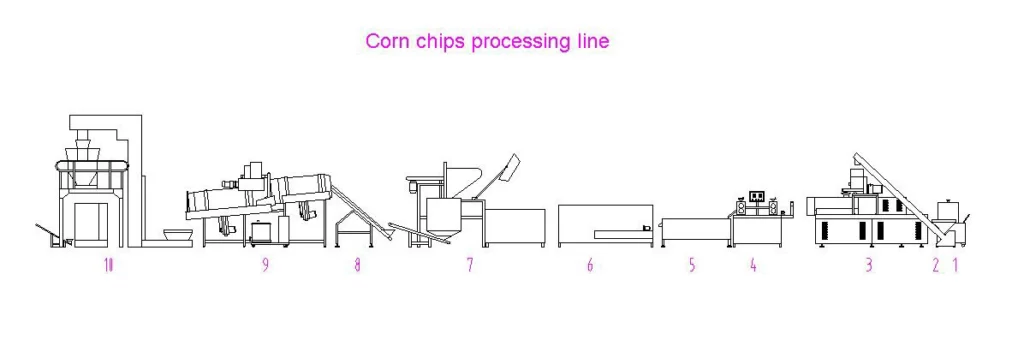

Corn chips production line is a specialized industrial machinery setup designed for the efficient and big capacity production of corn chips, a popular snack food. This production line typically consists of several key components and processes, which work together to produce high-quality corn chips in a consistent and automated manner.

The corn chips production line is a industrial equipment designed for efficiently and consistently producing high-quality corn chips. Whether you are a small-scale snack manufacturer or a large-scale production facility, this production line offers a complete solution to meet your corn chip production needs.

Corn Chips Making Line Key Features:

Extrusion System:

High-capacity extruder with adjustable parameters to produce a wide variety of corn chip shapes, sizes, and textures.

Precise control of temperature and pressure for optimal corn chip consistency.

Raw Material Handling:

Compatible with corn flour, and other corn-based ingredients.

Advanced mixing and conditioning equipment to ensure uniform dough quality.

Die and Cutting System:

A selection of customizable dies and cutting mechanisms for creating various corn chip shapes, including traditional triangle, rectangle, or specialty shapes.

Precision cutting ensures uniform chip sizes.

Conveyor and Drying System:

Continuous conveyor belt system for smooth chip transport through the drying process.

Efficient drying techniques, including hot air or infrared methods, to achieve the desired moisture content and texture.

Seasoning and Flavoring:

Integration of seasoning and flavoring systems for adding a wide range of flavors and coatings to the chips.

Adjustable seasoning distribution for consistent flavor application.

Cooling and Packaging:

Cooling system to reduce chip temperature before packaging.

Packaging equipment options for bagging, sealing, and labeling.

Control and Automation:

User-friendly control panel with a touch-screen interface for easy operation and monitoring.

Automation features for efficient and consistent production.

Corn Chips Machine Benefits:

Increased Efficiency: The Corn Chips Extruder Production Line allows for high-speed, continuous production, minimizing downtime and optimizing your output.

Versatile Product Range: Easily switch between various corn chip shapes and sizes to meet market demands or create signature products.

Consistent Quality: Precise control over the extrusion process and seasoning application ensures uniform quality in every batch.

Customization: Tailor the equipment configuration to suit your specific production needs and product requirements.

Reduced Labor Costs: Automation and easy-to-use controls minimize the need for manual labor and reduce the risk of human error.

Enhanced Flavor Options: Experiment with different flavors and coatings to create unique and appealing corn chip variations.

The Corn Chips Production Line is the perfect solution for businesses looking to expand or streamline their corn chip production, ensuring the highest quality, consistency, and efficiency in the process. Whether you are entering the snack food market or upgrading your existing production line, this equipment will help you meet the demands of today’s consumers.

The capacity of the corn chips production line.

AVN65 extruder machine has capacity 120-150 kg per hour.

AVN70 extruder machine has capacity 200-250 kg per hour.

AVN85 extruder machine has capacity 500-800 kg per hour.

Welcome your inquire on corn chips production line.