Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

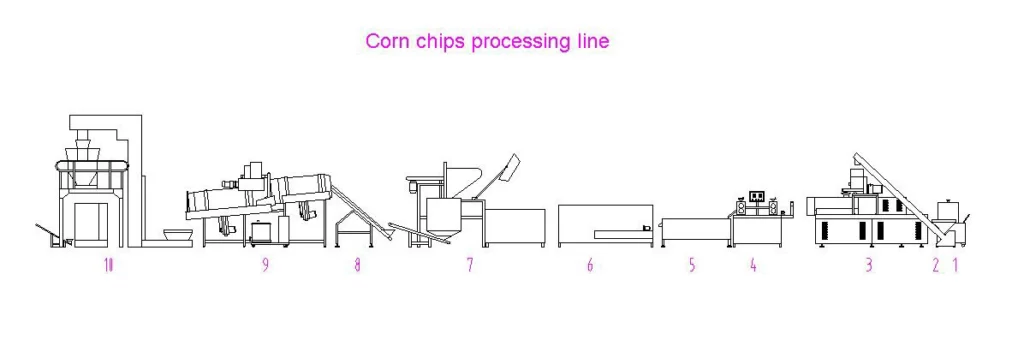

The machine as a continuous extrusion process to form doritos from a mixture of corn powder (dough) or other suitable ingredients. This method ensures a uniform product shape and texture, minimizing waste and ensuring a high-quality end product.

The Continuous extrusion doritos machine is an advanced and specialized piece of food processing equipment designed for the efficient and continuous production of delicious and popular snack items known as Doritos. These machines are a critical component in the manufacturing process of Doritos, offering automation and precision to ensure consistent product quality and high production capacity.

Key Features and Benefits:

Continuous Extrusion Technology: The machine employs a continuous extrusion process to form Doritos from a mixture of corn powder (dough) or other suitable ingredients. This method ensures a uniform product shape and texture, minimizing waste and ensuring a high-quality end product.

High Production Capacity: Designed for industrial-scale production, the machine can produce a large volume of Doritos in a relatively short time, making it suitable for large-scale snack food manufacturing facilities.

Customizable Shapes and Flavors: The equipment can be easily adapted to create various shapes, sizes, and flavors of Doritos, allowing manufacturers to cater to different market preferences and expand their product offerings.

Precise Control: The machine offers precise control over the thickness and texture of the extruded product, ensuring consistency in every batch.

Easy Operation and Maintenance: Designed with user-friendliness in mind, the Continuous Extrusion Doritos Machine is easy to operate, clean, and maintain, reducing downtime and production costs.

Stainless Steel Construction: The machine is typically constructed using food-grade stainless steel, ensuring durability, hygiene, and compliance with food safety standards.

Integrated Safety Features: Safety mechanisms and features are built into the machine to protect operators and prevent accidents during operation.

Energy Efficiency: Designed to optimize energy usage, the machine aims to reduce operating costs and environmental impact.

Applications:

The Continuous Doritos Machine is primarily used by snack food manufacturers for the large-scale production of Doritos and similar extruded snacks. It is a versatile solution for producing a variety of shapes and flavors, allowing companies to meet the demands of diverse consumer markets.

By investing in a Continuous Doritos Machine, snack food producers can enhance their production efficiency, reduce labor costs, maintain product consistency, and expand their product portfolio to stay competitive in the snack food industry.

The capacity of the doritos machine.

AVN65 extruder machine has capacity 120-150 kg per hour.

AVN70 extruder machine has capacity 200-250 kg per hour.

AVN85 extruder machine has capacity 500-800 kg per hour.

Welcome your inquire on doritos machine.