Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

Artificial Rice Production Line is a manufacturing process used to produce a type of rice substitute made from various grains, typically rice flour or a mixture of rice and other ingredients. Artificial rice, also known as synthetic rice or fortified rice.

Artificial Rice Production Line

Artificial Rice Production Line is a manufacturing process used to produce a type of rice substitute made from various grains, typically rice flour or a mixture of rice and other ingredients. Artificial rice, also known as synthetic rice or fortified rice, is produced for various reasons, including addressing food shortages, improving nutrition, or creating more shelf-stable rice products.

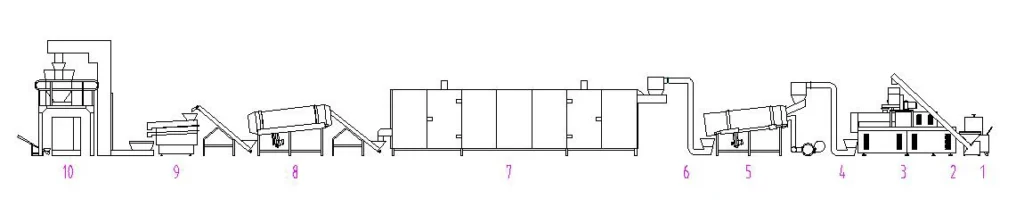

Artificial rice production line flow chart.

Mixer machine—conveyor machine—Instant rice extruder machine—drum machine—dryer machine—packing machine.

Raw Material Preparation: The production process begins with the preparation of raw materials. The primary ingredient is rice flour, but other grains such as wheat, corn, or barley can also be used. These grains are cleaned, washed, and milled to create a fine flour.

Fortification and Mixing: To improve the nutritional value of artificial rice, various vitamins, minerals, and additives may be added. These can include nutrients like vitamin A, iron, and folic acid. The ingredients are mixed thoroughly to ensure even distribution.

Extrusion or Shaping: The rice flour mixture is processed through an extruder or shaping machine. This equipment forms the mixture into rice-like grains or shapes. The extrusion process may involve heat and pressure to cook the mixture and give it a rice-like texture.

Drying: The shaped artificial rice is dried to remove moisture, making it shelf-stable and preventing spoilage. Drying methods can include hot air drying or infrared drying.

Cooling: After drying, the artificial rice is cooled to room temperature to prevent moisture condensation in packaging.

Packaging: The artificial rice is packaged into various sizes and types of containers, such as bags or vacuum-sealed pouches. Packaging is designed to protect the product from environmental factors and maintain its shelf life.

Quality Control: Throughout the production process, quality control measures are in place to ensure the artificial rice meets safety and quality standards. This includes checks for consistency in texture, color, nutritional content, and taste.

The artificial rice production line capacity.

| Item | AVN65 | AVN70 | AVN75 | AVN85 | AVN95 |

| Capacity | 100 kg/h | 200 kg/h | 300 kg/h | 500 kg/h | 800 kg/h |

The advantage of artificial rice production line.

1. Materials is adjustable. You could change the recipe according to local market.

2. Automatic. Machine line could work continuously.

3. Saving labor cost.

4. Big capacity.

5. Food grade machines, no pullution.

6. Machines are easy to operate and clean.

Welcome your iqnuiry on artificial rice production line.