Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

Instant rice it is designed to self heating rice pot which is well saled in the market.

Instant rice is a white rice or yellow rice, that is partly precooked, dehydrated and packed in a dried rice box. That process of instant rice make it allows to be later cooked and a typical cooking time of 5 minutes. Now it is designed to self-heating rice pot which is well saled in the market.

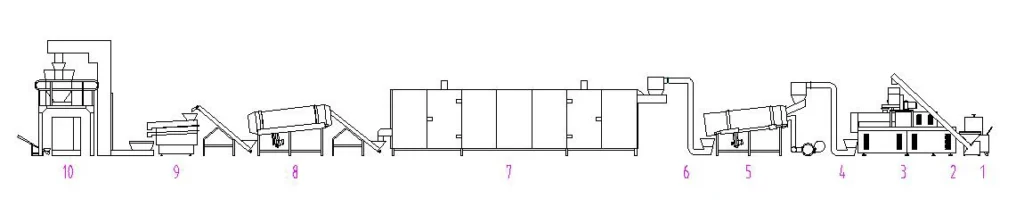

Instant rice machine line flow chart.

Mixer machine—conveyor machine—Instant rice extruder machine—drum machine—dryer machine—packing machine.

1. The mixer machine. Stainless steel machine, which is used to mix FRK materials together.

2. Conveyor machine. Lift the frk materials into extruder hopper.

3. FRK extruder machine. Shape material into rice.

4. Air conveyor. Make FRK transported to next machine.

5. Dum rice polishing machine.

6. Dryer machine. Moisture dehydrator to make sure FRK storage.

7. Packing machine.

The Instant Rice Machine Capacity.

| Item | AVN65 | AVN70 | AVN75 | AVN85 | AVN95 |

| Capacity | 100 kg/h | 200 kg/h | 300 kg/h | 500 kg/h | 800 kg/h |

The advantage of Instant Rice Machine.

1. Materials is adjustable. You could change the recipe according to local market.

2. Automatic. Machine line could work continuously.

3. Saving labor cost.

4. Big capacity.

5. Food grade machines, no pullution.

6. Machines are easy to operate and clean.

Welcome your iqnuiry on Instant Rice Machine.