Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

Fortified Rice Machine is a specialized piece of equipment used in the production of fortified rice kernels (FRK), with big capacity and automaticly producing.

Fortified rice is artifical rice that has been enriched with additional nutrients . Common nutrients added to fortified rice include iron, folic acid, vitamin A, and vitamin B1. This fortification process aims to combat deficiencies in these nutrients, particularly in populations where rice is a staple food and these deficiencies are prevalent like India.

Rice extruder machine is a specialized piece of equipment used in the production of fortified rice kernels (FRK), with big capacity and automaticly producing.

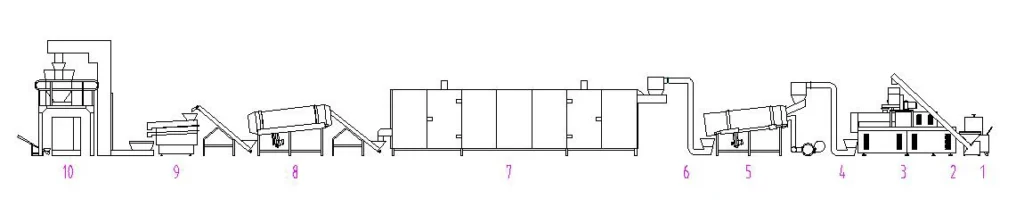

FRK extruder machine line flow chart.

1. The mixer machine. Stainless steel machine, which is used to mix FRK materials together.

2. Conveyor machine. Lift the frk materials into extruder hopper.

3. FRK extruder machine. Shape material into rice.

4. Air conveyor. Make FRK transported to next machine.

5. Dum rice polishing machine.

6. Dryer machine. Moisture dehydrator to make sure FRK storage.

7. Packing machine.

The FRK Fortified Rice Machine Capacity.

AVN65 machine line has capacity 100 kg per hour.

AVN70 Machine line has capacity 200 kg per hour.

AVN75 machine line has caapcity 400 kg per hour.

AVN85 machine line has capacity 500 kg per hour.

AVN95 machine line has capacity 800-1000 kg per hour.

The advantage of Fortified Rice Machine.

1. Materials is adjustable. You could change the recipe according to local market.

2. Automatic. Machine line could work continuously.

3. Saving labor cost.

4. Big capacity.

5. Food grade machines, no pullution.

6. Machines are easy to operate and clean.

Welcome your iqnuiry on fortified rice machine.