Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

The rice fortification extruder machine is a specialized piece of equipment used in the food processing industry to fortify rice with essential nutrients and vitamins.

The rice fortification extruder machine is a specialized piece of equipment used in the food processing industry to fortify rice with essential nutrients and vitamins. Rice fortification is a process that involves adding micronutrients like vitamins and minerals to rice to improve its nutritional value and address nutrient deficiencies in populations that rely heavily on rice as a staple food.

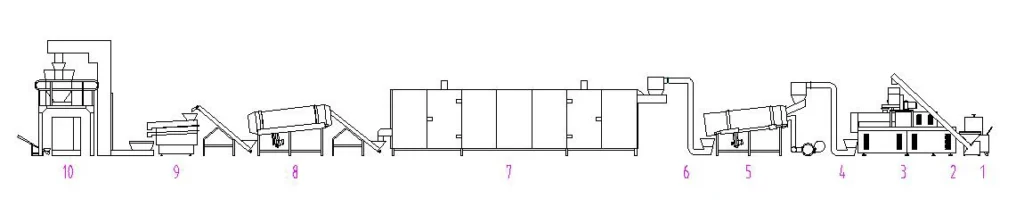

The flow chart of rice fortification extruder machine

Mixer machine—Conveyor—Extruder machine—Vibrate cooling—Conveyor—Dryer machine—Cooling machine

1. The mixer machine. Stainless steel machine, which is used to mix FRK materials together.

2. Conveyor machine. Lift the frk materials into extruder hopper.

3. FRK extruder machine. Shape material into rice.

4. Air conveyor. Make FRK transported to next machine.

5. Dum rice polishing machine.

6. Dryer machine. Moisture dehydrator to make sure FRK storage.

7. Packing machine.

The rice fortification extruder machine works by mixing rice flour with a premixed blend of vitamins and minerals in precise quantities. This mixture is then extruded, which means it is pushed through a die or nozzle under high pressure and temperature. As the mixture passes through the extruder, it undergoes a combination of heat, shear forces, and pressure, causing it to expand and change in texture. The extruded rice product is then dried and milled to produce fortified rice grains.

The specific vitamins and minerals added to the rice can vary, but common fortificants include iron, folic acid, vitamin A, and vitamin B-complex. Fortified rice helps combat nutrient deficiencies in populations where rice is a primary dietary staple, contributing to improved public health.

Fortified rice is an important strategy in addressing malnutrition and improving the overall health of communities, especially in regions where rice consumption is widespread. The use of rice fortification extruder machines is a key step in the production of fortified rice, ensuring that the added nutrients are evenly distributed throughout the rice grains.

The rice fortification extruder machine capacity.

AVN65 machine line has capacity 100 kg per hour.

AVN70 Machine line has capacity 200 kg per hour.

AVN75 machine line has caapcity 400 kg per hour.

AVN85 machine line has capacity 500 kg per hour.

AVN95 machine line has capacity 800-1000 kg per hour.

Welcome your inquiry on rice fortification extruder machine.