Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

This extrusion machine is engineered to produce consistent and superior-quality bread crumbs, which are essential for a wide range of food products like breaded and fried foods, toppings, and coatings.

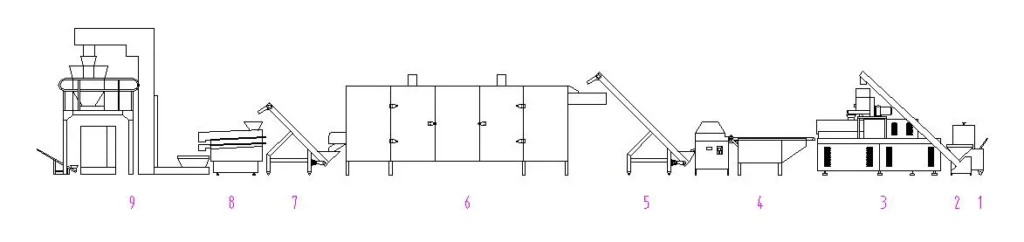

The Bread Crumbs Food Machine is a versatile and efficient industrial equipment designed for the production of high-quality bread crumbs. This machine is an essential tool for food processing facilities, bakeries, and food manufacturers, enabling them to create uniform, crispy, and golden bread crumbs that can be used in a variety of culinary applications.

Key Features:

High-Quality Bread Crumbs: This extrusion machine is engineered to produce consistent and superior-quality bread crumbs, which are essential for a wide range of food products like breaded and fried foods, toppings, and coatings.

Customization: The machine allows for customization of bread crumb size, shape, and texture, ensuring that you can meet the specific requirements of your products.

Efficiency: It operates with high efficiency, minimizing product waste and maximizing production output. This results in cost savings for your business.

Easy Operation: The user-friendly control panel and interface make it easy to operate and adjust settings, reducing the learning curve for your operators.

Durable Construction: The machine is built with robust and food-grade materials, ensuring longevity and easy maintenance.

Hygienic Design: It complies with strict hygiene and safety standards, featuring easy-to-clean surfaces and components, essential in food processing environments.

Versatile Applications: The bread crumbs produced by this machine can be used as coatings for fried and baked foods, enhancing their texture and flavor. They can also serve as a base for meatloaf, meatballs, and various culinary applications.

Cost-Effective: By producing your bread crumbs in-house, you can reduce the costs associated with purchasing pre-made crumbs, resulting in substantial savings over time.

Consistency: The machine ensures consistent product quality, which is vital for maintaining the integrity of your food products and meeting customer expectations.

Safety Features: The machine is equipped with safety measures to protect operators during operation, including emergency stop functions and protective guards.

The Bread Crumbs Food Machine is a valuable addition to any food processing facility, allowing you to take control of your breadcrumb production, enhance product quality, and reduce operational costs. Whether you are in the food manufacturing, restaurant, or bakery business, this machine is an excellent investment to improve the quality of your products and streamline your production process.

The capacity of the bread crumbs food machine.

AVN65 extruder machine has capacity 120-150 kg per hour.

AVN70 extruder machine has capacity 200-250 kg per hour.

AVN85 extruder machine has capacity 500-800 kg per hour.

AVN95 extruder machine has capacity 1000-1200 kg per hour.

Welcome your inquire on bread crumbs food machine.