Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

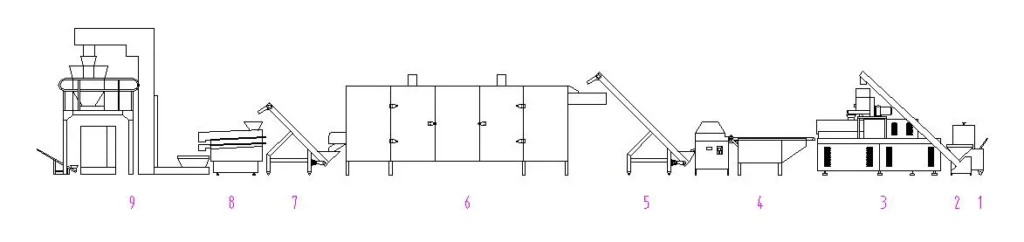

The Bread Crumbs Production Line is an advanced and highly efficient industrial system designed for the automated and large-scale manufacturing of high-quality breadcrumbs.

The Bread Crumbs Production Line is an advanced and highly efficient industrial system designed for the automated and large-scale manufacturing of high-quality breadcrumbs. This versatile production line is an essential asset for food manufacturers, bakeries, and food processing facilities seeking to produce consistent, crispy, and flavorful breadcrumbs for a wide range of culinary applications.

Key Features:

Bread Crumb Extrusion: The production line is equipped with a extrusion system that ensures uniform texture and size of breadcrumbs. It can produce various shapes and sizes of breadcrumbs to meet diverse customer requirements.

Efficient Drying System: A carefully designed drying system ensures that the breadcrumbs are dried to the desired moisture content for extended shelf life and superior crispiness.

Sifting and Grading: The production line features a sifting and grading section to eliminate oversized and undersized particles, resulting in consistent, high-quality breadcrumbs.

User-Friendly Control Panel: An intuitive control panel with a user-friendly interface allows operators to monitor and adjust production parameters easily. It provides real-time data on production efficiency and quality control.

Variable Production Capacities: The Bread Crumbs Extruder Production Line is available in various production capacities to suit the needs of small, medium, and large-scale operations.

Quality Assurance: Stringent quality control measures are integrated into the production process to ensure that the breadcrumbs meet the highest industry standards for texture, flavor, and consistency.

Easy Maintenance: The production line is designed for ease of maintenance, with accessible components and straightforward servicing procedures.

Applications: The Bread Crumbs Production Line is ideal for producing breadcrumbs that find application in a wide range of food products, including:

In summary, the Bread Crumbs Extruder Production Line is a dependable, efficient, and customizable solution for businesses involved in food production. It streamlines the breadcrumb manufacturing process, resulting in high-quality, consistent breadcrumbs that enhance the texture and flavor of a variety of culinary creations.

The capacity of the bread crumbs production line.

AVN65 extruder machine has capacity 120-150 kg per hour.

AVN70 extruder machine has capacity 200-250 kg per hour.

AVN85 extruder machine has capacity 500-800 kg per hour.

AVN95 extruder machine has capacity 1000-1200 kg per hour.

Welcome your inquire on bread crumbs production line.