Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

Extrusion is a common process used in the food industry to produce various products, including modified potato starch. During extrusion, starchy materials are subjected to high temperature and pressure, resulting in gelatinization and modification of their properties.

Extrusion is a common process used in the food industry to produce various products, including modified potato starch. During extrusion, starchy materials are subjected to high temperature and pressure, resulting in gelatinization and modification of their properties.

The extrusion of modified potato starch:

Feeder: A feeder is used to introduce the potato starch mixture into the extruder. Accurate feeding is crucial to control the process and product quality.

Steam Injector: Steam may be injected into the extruder barrel to provide moisture, which is essential for gelatinization and modification of starch. This ensures that the potato starch mixture reaches the desired consistency.

Die and Cutter: The die at the end of the extruder determines the shape and size of the extruded product. There may also be a cutter or slicer to cut the extruded product into the desired lengths or shapes. The design of the die and cutter can be customized for specific product requirements.

Dryer: Depending on the final moisture content required for the modified potato starch, it may go through a drying process after extrusion. Dryers can be used to reduce the moisture content to the desired level.

Quality Control Equipment: Various sensors and instruments can be used to monitor and control the extrusion process. This may include temperature sensors, pressure gauges, and moisture analyzers to ensure product consistency and quality.

Packaging Equipment: Once the modified potato starch is produced, it is typically packaged for distribution. This can involve bagging machines, filling equipment, and labeling machines.

Safety and Monitoring Systems: Safety is a paramount concern in extrusion processes due to the high temperatures and pressures involved. Equipment for safety measures, such as emergency stop systems and monitoring tools, should be in place.

Modified starches find applications in various industries, including the food industry (for thickening sauces, soups, and gravies), the paper industry (as a binder and surface treatment), the textile industry (as a sizing agent), and many other sectors where modified starch properties can be beneficial. The choice of modification method and source material depends on the desired properties and intended use of the modified starch.

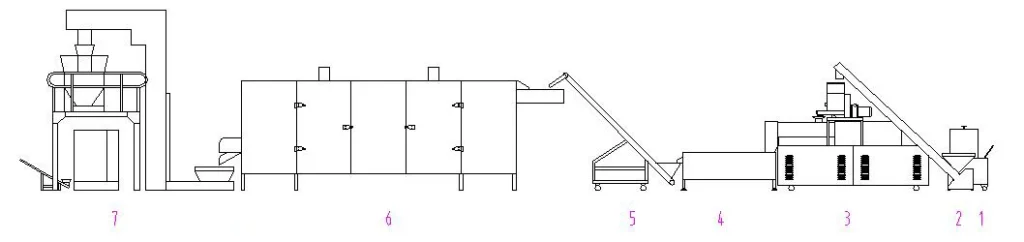

The modified starch extruder machine flow chart.

Mixer machine—conveyor—extruder machine—conveyor—dryer—grinder machine

The capacity of the modified potato starch equipment.

AVN65 starch extruder machine has capacity 120 kg per hour.

AVN70 starch extruder machine has capacity 200 kg per hour.

AVN85 starch extruder machine has capacity 500 kg per hour.

The specific equipment and settings used in the extrusion process for modified potato starch may vary depending on the desired end product, whether it’s in the form of granules, pellets, or other shapes. The control of temperature, pressure, and moisture levels is critical to achieving the desired modifications and quality of the modified starch.

Weclome your inquiry on modified potato starch equipment.