Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

Wheat modified starch production line is a specialized system used in the food processing industry to produce modified wheat starch.

Wheat modified starch production line is a specialized system used in the food processing industry to produce modified wheat starch. Modified starches are starch products that have been chemically or physically altered to improve their functionality for various applications, such as in the food, pharmaceutical, and industrial sectors. Extrusion is one of the common methods used to modify starch, and it involves the use of high temperature and pressure to change the properties of starch granules.

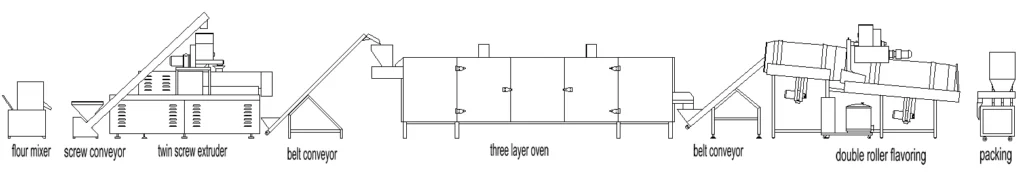

Wheat Modified Starch Extrusion Production Line:

Raw Material Handling: The process begins with the handling and preparation of wheat flour, which is the primary raw material. The wheat flour is typically blended with water to form a slurry or dough.

Mixing and Conditioning: The wheat flour slurry may be mixed and conditioned to achieve the desired consistency and uniformity. This step ensures that the moisture content is suitable for extrusion.

Extrusion: The prepared slurry is fed into an extruder, which is a specialized machine designed for extrusion processes. The extruder subjects the slurry to high temperature and pressure conditions, causing the starch granules to undergo physical and chemical changes. This can involve shearing, heat, and pressure to modify the starch properties.

Cutting and Shaping: After extrusion, the modified starch is shaped and cut into the desired form. This can include granules, flakes, or other shapes depending on the intended application.

Drying: The extruded starch product may be dried to reduce its moisture content. Drying can be accomplished through various methods, such as hot air drying or fluidized bed drying.

Cooling: The modified starch is then cooled to ensure it reaches a stable temperature suitable for storage and packaging.

Packaging: The final product is packaged in various containers based on customer requirements. Modified wheat starch can be used in various food products as a thickening agent, stabilizer, or gelling agent.

Quality Control: Throughout the production process, quality control checks are performed to ensure the product meets the required specifications in terms of moisture content, texture, and other relevant characteristics.

It’s important to note that the specifics of a Wheat Modified Starch Extrusion Production Line may vary depending on the manufacturer and the intended application of the modified starch. The line may be customized to produce different types of modified starch with specific properties tailored to various industries.

Additionally, safety and hygiene standards are crucial in food processing, so the production line would adhere to relevant regulations and standards to ensure the safety and quality of the final product.

The capacity of wheat modified starch production line.

AVN65 extruder machine has capacity 120-150 kg per hour.

AVN70 extruder machine has capacity 200-250 kg per hour.

AVN85 extruder machine has capacity 500-800 kg per hour.

AVN95 extruder machine has capacity 1000-1200 kg per hour.

Welcome your inquire on wheat modified starch production line.