Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

The modified starch extruder machine is a piece of industrial equipment used to process starch and modify its properties for various applications in the food, paper, textile, and other industries. Starch is a carbohydrate commonly found in plants and is used in many products due to its thickening, gelling, and binding properties. Modified starches are created by altering the starch’s molecular structure to enhance its functionality, stability, or other desired characteristics.

The modified starch extruder machine is a piece of industrial equipment used to process starch and modify its properties for various applications in the food, paper, textile, and other industries. Starch is a carbohydrate commonly found in plants and is used in many products due to its thickening, gelling, and binding properties. Modified starches are created by altering the starch’s molecular structure to enhance its functionality, stability, or other desired characteristics.

How a modified starch extruder machine works and its applications:

Raw Material Handling: The process typically begins with the introduction of raw starch material, which can be from various sources like corn, wheat, or potatoes. The starch may need to be mixed with water or other additives to create a slurry.

Extrusion: The prepared starch slurry is fed into the extruder machine. The extruder consists of a barrel, a screw or auger, and a die at the end. The screw rotates and pushes the slurry through the barrel. As the slurry passes through the barrel, it is subjected to heat, pressure, and mechanical shear forces.

Cooking and Gelatinization: During the extrusion process, the starch slurry undergoes cooking and gelatinization. The combination of heat and shear forces breaks down the starch granules and rearranges their molecular structure. This results in modified starch with improved characteristics, such as better thickening or gelling properties.

Cooling and Shaping: After passing through the die, the modified starch is extruded into a specific shape or form, depending on the desired application. The extruded product is then cooled, solidified, and cut into the desired size or shape.

Applications of modified starch produced with extruder machines include:

Food Industry: Modified starches are used in a wide range of food products, including soups, sauces, bakery items, snacks, and confectionery, to improve texture, stability, and mouthfeel.

Paper Industry: Modified starch is used as a binder and coating agent in the production of paper and cardboard products.

Textile Industry: In textile sizing, modified starch is used to improve the weaving process by providing adhesion and smoothness to the fibers.

Pharmaceuticals: Starch can be modified for pharmaceutical use, such as in tablet formulations.

Biodegradable Plastics: Some modified starches are used in the production of biodegradable plastics.

Modified starches find applications in various industries, including the food industry (for thickening sauces, soups, and gravies), the paper industry (as a binder and surface treatment), the textile industry (as a sizing agent), and many other sectors where modified starch properties can be beneficial. The choice of modification method and source material depends on the desired properties and intended use of the modified starch.

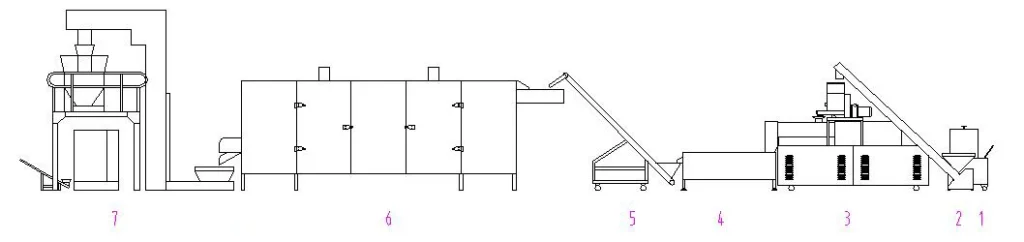

The modified starch extruder machine flow chart.

Mixer machine—conveyor—extruder machine—conveyor—dryer—grinder machine

The capacity of the modified starch extruder machine.

AVN65 starch extruder machine has capacity 120 kg per hour.

AVN70 starch extruder machine has capacity 200 kg per hour.

AVN85 starch extruder machine has capacity 500 kg per hour.

The specific parameters, temperature, pressure, and additives used during the extrusion process can be customized to achieve the desired modifications in starch properties. These machines come in various sizes and configurations, depending on the scale of production and the specific application requirements.

Weclome your inquiry on modified starch extruder machine.