Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

The machine utilizes advanced extrusion technology, combining heat, pressure, and mechanical action to modify cassava starch effectively. It promotes the gelatinization of starch granules, resulting in a pregelatinized product.

The Pregelatinized modified cassava starch processing machine is a highly specialized and versatile industrial equipment designed for the production of pregelatinized modified cassava starch. This machine is crucial for cassava starch processing, where the starch undergoes modification to enhance its properties, making it suitable for various applications in the food, pharmaceutical, and industrial sectors.

Key Features:

Extrusion Technology: The machine utilizes advanced extrusion technology, combining heat, pressure, and mechanical action to modify cassava starch effectively. It promotes the gelatinization of starch granules, resulting in a pregelatinized product.

Precision Control: Equipped with a user-friendly control interface, operators can adjust and fine-tune parameters such as temperature, moisture content, screw speed, and pressure to ensure precise and consistent product quality.

Material Handling System: The feeding system efficiently handles raw cassava starch, additives, and water to create a uniform and well-mixed starch slurry.

Versatile Die and Cutter Options: The extrusion machine includes customizable die and cutter options, allowing for the production of a wide range of product shapes and sizes, making it adaptable for various applications.

Drying and Cooling: Depending on the final product requirements, the machine can incorporate a drying system to reduce moisture content and a cooling unit to ensure safe handling of the modified starch.

Hygiene and Safety Features: Designed with operator safety in mind, the machine includes safety interlocks, guards, and easy-to-clean components to maintain a hygienic processing environment.

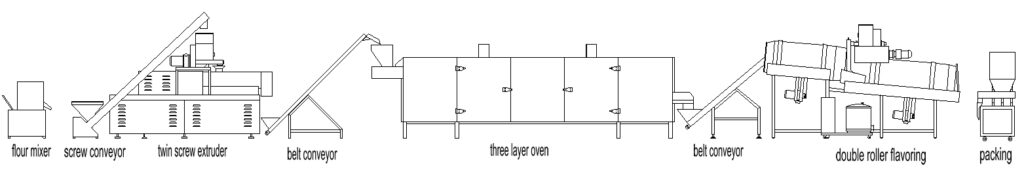

The flow chart of modified starch machine line.

Applications: The pregelatinized modified cassava starch extrusion processing machine finds applications in multiple industries, including:

Benefits:

The Pregelatinized Modified Cassava Starch Processing Machine is an essential tool for manufacturers seeking to produce high-quality modified cassava starch for various applications. Its adaptability, automation, and precision control make it an indispensable asset for businesses operating in sectors where modified cassava starch is a crucial ingredient.

The capacity of the modified cassava starch processing machine.

AVN65 extruder machine has capacity 120-150 kg per hour.

AVN70 extruder machine has capacity 200-250 kg per hour.

AVN85 extruder machine has capacity 500-800 kg per hour.

AVN95 extruder machine has capacity 1000-1200 kg per hour.

Welcome your inquire on modified cassava starch processing machine.