Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

The modified tapioca starch extruder processing line typically refers to a production line or manufacturing setup used to process tapioca starch through extrusion. Extrusion is a process in which a material, in this case, tapioca starch, is pushed through a die or a mold to create specific shapes or forms. Tapioca starch is often extruded to make various products like noodles, snacks, or other food items.

The modified tapioca starch extruder processing line:

Raw Material Handling: The process begins with the handling of tapioca starch. This includes sourcing, quality control, and storage of tapioca starch in a controlled environment to prevent moisture absorption.

Mixing and Blending: Depending on the desired product, tapioca starch may be mixed with water and other ingredients to create a uniform dough or slurry. This step is essential for achieving the desired texture and flavor.

Extrusion: The mixed tapioca starch is fed into an extruder. The extruder typically consists of a barrel with a screw conveyor that pushes the material through a die or nozzle. The choice of die shape and size determines the final product’s form. For instance, flat noodles require a different die than spherical snacks.

Cutting and Shaping: Once the tapioca starch dough is extruded, it is cut and shaped into the desired product form. This can be done using cutting blades, rollers, or other mechanisms specific to the product being manufactured.

Drying: The extruded products usually contain a significant amount of moisture, and drying is essential to reduce the moisture content. Depending on the product, this can be done through various methods, such as hot air drying, microwave drying, or frying for certain snacks.

Cooling: After drying, the products are often cooled to room temperature or a specified temperature to make them ready for packaging.

Packaging: The final tapioca starch products are packed into bags, boxes, or other suitable containers. The packaging material and methods can vary depending on the product and market requirements.

Quality Control: At various stages of the processing line, quality control measures are in place to ensure that the products meet the required standards in terms of texture, taste, appearance, and safety.

Automation and Controls: Modern processing lines often incorporate automation and control systems to monitor and adjust various parameters, such as temperature, pressure, and extrusion speed, to maintain product consistency.

Cleaning and Maintenance: Regular cleaning and maintenance of the processing equipment are crucial to ensure the line operates efficiently and safely.

Safety Measures: Safety protocols, including personnel training and the use of safety equipment, are essential to ensure a safe working environment.

Modified starches find applications in various industries, including the food industry (for thickening sauces, soups, and gravies), the paper industry (as a binder and surface treatment), the textile industry (as a sizing agent), and many other sectors where modified starch properties can be beneficial. The choice of modification method and source material depends on the desired properties and intended use of the modified starch.

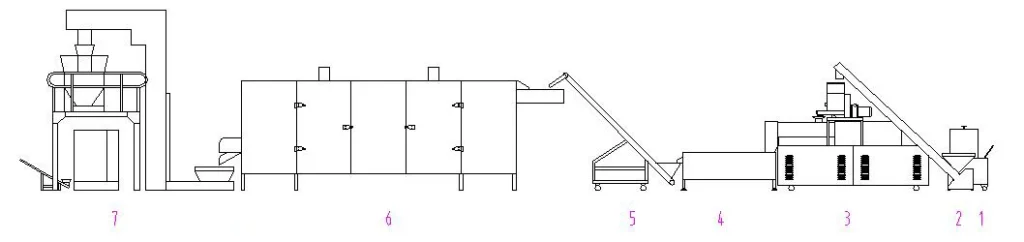

The modified tapioca starch extruder processing line flow chart.

Mixer machine—conveyor—extruder machine—conveyor—dryer—grinder machine

The capacity of the modified tapioca starch extruder processing line.

AVN65 starch extruder machine has capacity 120 kg per hour.

AVN70 starch extruder machine has capacity 200 kg per hour.

AVN85 starch extruder machine has capacity 500 kg per hour.

The specifics of a modified tapioca starch extruder processing line can vary depending on the intended end products and the scale of production. This process is commonly used in the food industry to create a wide range of tapioca starch-based products, such as pasta, snacks, and more.

Weclome your inquiry on modified tapioca starch extruder processing line.