Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

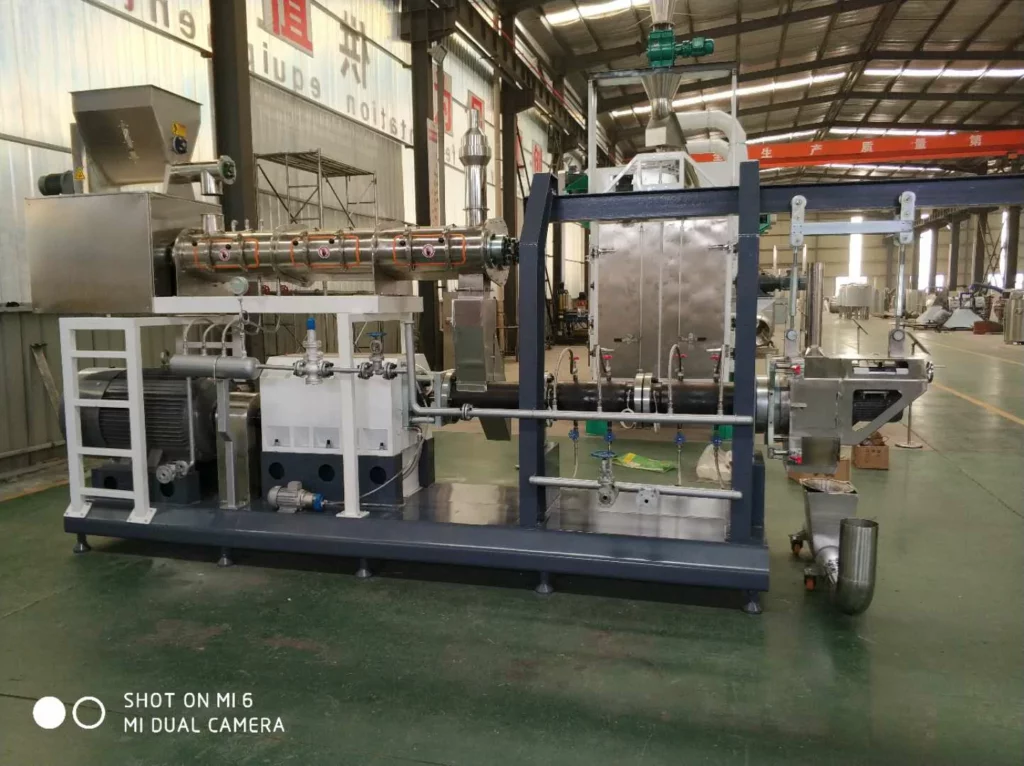

The puff snack extruder, also known as an extrusion machine or puffing machine, is a specialized piece of equipment used in the food processing industry to create a wide range of puffed or expanded snacks. These machines are commonly used to produce snacks like cheese puffs, corn puffs, and various extruded snacks with different shapes, textures, and flavors.

The puff snack extruder, also known as an extrusion machine or puffing machine, is a specialized piece of equipment used in the food processing industry to create a wide range of puffed or expanded snacks. These machines are commonly used to produce snacks like cheese puffs, corn puffs, and various extruded snacks with different shapes, textures, and flavors.

The puff snack extruder typically works:

Ingredient Mixing: The process begins with the preparation of a mixture of raw ingredients. These ingredients often include starches, grains (such as corn or rice), water, seasonings, and sometimes fats or oils. This mixture is thoroughly blended to create a homogeneous dough or batter.

Extrusion: The prepared mixture is fed into the extruder. Inside the extruder, there is a screw conveyor that rotates and pushes the mixture through a barrel with tightly fitted screws. As the mixture moves through the barrel, it undergoes both mechanical shear and heat from friction.

Pressure and Temperature Increase: The combination of mechanical shear and heat causes the mixture to undergo changes in pressure and temperature. As the mixture is forced through a narrow opening called a die, the sudden release of pressure causes it to expand rapidly. This expansion forms the characteristic puffy texture of the snack.

Cutting and Shaping: After extrusion, the puffed snack mass is typically cut or shaped into the desired snack form. Various cutting and shaping dies can be used to create different snack shapes and sizes.

Drying and Seasoning: The freshly extruded snacks may be dried to remove excess moisture and then seasoned with flavorings, spices, and coatings to enhance their taste.

Cooling and Packaging: The finished puffed snacks are allowed to cool before being packaged in bags, boxes, or other containers for distribution and sale.

Puff snack extruders come in various sizes and configurations, allowing manufacturers to produce a wide variety of snack products. They are a popular choice for snack production due to their versatility, efficiency, and ability to create snacks with appealing textures and flavors.

What is the capacity of puff snack extruder?

AVN65 extruder has capacity 120-150 kg per hour.

AVN70 extruder has capacity 200-250 kg per hour.

AVN85 extruder has capacity 500-800 kg per hour,

AVN95 extruder has capacity 1000-1200 kg per hour.