Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

The twin-screw food extruder is a machine used in the food processing industry to produce a wide variety of food products through the extrusion process. Extrusion is a versatile and efficient method for transforming raw ingredients into finished food products with different shapes and textures.

The twin-screw food extruder is a machine used in the food processing industry to produce a wide variety of food products through the extrusion process. Extrusion is a versatile and efficient method for transforming raw ingredients into finished food products with different shapes and textures. The twin-screw design refers to the presence of two intermeshing screws within the extruder barrel, which are responsible for mixing, cooking, and shaping the food materials.

The key features and functions of a twin-screw food extruder:

Mixing: The twin screws rotate in opposite directions, effectively mixing and kneading the ingredients. This is particularly important for creating uniform blends of various components, such as flours, starches, fats, proteins, and additives.

Cooking: Twin-screw extruders can simultaneously mix and cook food ingredients due to the combination of mechanical shear and heat generated during the extrusion process. This is crucial for products like breakfast cereals, snack foods, and pet food.

Shearing: The screws apply shear forces to the food material, which helps modify the structure and texture of the final product. Shearing is especially beneficial for creating products with specific textures, like textured vegetable protein or meat analogs.

Shaping: The extrusion die at the end of the barrel imparts the desired shape and size to the product. Different dies can be used to produce various product shapes, such as pasta, snacks, or pet kibble.

Control: Twin-screw food extruders allow precise control over process parameters, such as temperature, pressure, and screw speed. This control is vital for achieving the desired product quality and characteristics.

Applications of twin-screw food extruders are extensive and include the production of:

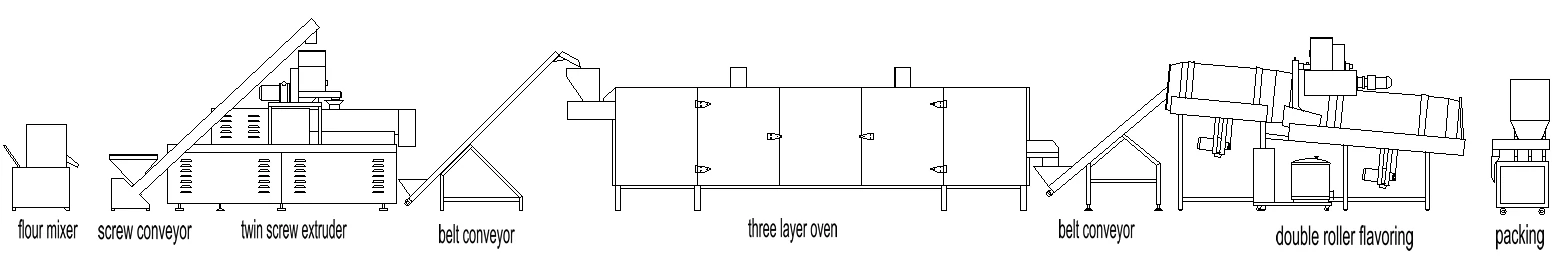

Puff snacks machine line includes mixer machine, conveyor machine, extruder machine, conveyor, dryer oven machine, drum flavoring machine.

AVN65 Machine line has capacity 120-150 kg per hour.

AVN70 Machine line has capacity 200-250 kg per hour.

AVN85 Machine line has capacity 500-800 kg per hour,

AVN95 Machine line has capacity 1000-1200 kg per hour.

The versatility and efficiency of twin-screw food extruders make them an essential piece of equipment in the food processing industry. They are employed in both large-scale food production facilities and smaller food laboratories for research and development purposes.

Extruder machine working video.