Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

The twin-screw extruder is a versatile machine commonly used in the food processing industry for the production of various snack products. It is especially popular for making extruded snacks such as cheese puffs, pretzels, cereal-based snacks, and more.

The twin-screw extruder is a versatile machine commonly used in the food processing industry for the production of various snack products. It is especially popular for making extruded snacks such as cheese puffs, pretzels, cereal-based snacks, and more.

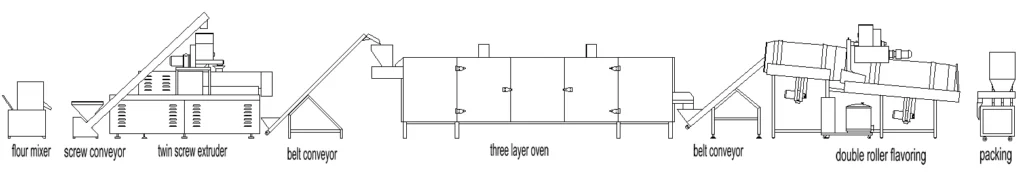

Here’s how a twin-screw extruder is typically used in snack production:

Ingredient Mixing: Dry ingredients such as cornmeal, wheat flour, rice, or potato flakes are mixed with water, fats, flavors, and additives in a batch mixer to create a uniform dough-like mixture.

Feeding the Extruder: The prepared dough is then fed into the twin-screw extruder. The extruder consists of two counter-rotating screws within a barrel.

Extrusion: Inside the extruder, the screws transport the dough along the barrel. As the dough moves through the extruder, it’s subjected to mechanical shear, heat, and pressure, which transform it into a semi-liquid state. At this point, steam can be injected into the mix to further cook the dough.

Die Plate: Near the end of the extruder, the dough passes through a die plate with specially designed holes or shapes. The pressure and heat cause the dough to expand as it passes through the die, creating the desired snack shape.

Cutting: Once the extruded dough exits the die, it’s cut into individual snack pieces. The cutting mechanism is usually synchronized with the extrusion speed to create consistent snack shapes.

Drying and Cooling: The freshly extruded snacks are then conveyed through a drying and cooling system to remove excess moisture and set their texture. This step is crucial for achieving the desired crispness or crunchiness.

Flavoring: After drying and cooling, the snacks can be flavored by spraying or dusting them with seasoning mixes or powders. The flavoring adheres to the snacks due to their residual moisture content.

Packaging: Finally, the snacks are conveyed to the packaging area where they are weighed, bagged, and sealed for distribution to consumers.

What is the capacity of twin-screw extruder?

AVN65 extruder has capacity 120-150 kg per hour.

AVN70 extruder has capacity 200-250 kg per hour.

AVN85 extruder has capacity 500-800 kg per hour,

AVN95 extruder has capacity 1000-1200 kg per hour.

Twin-screw extruders offer several advantages for snack production, including precise control over the extrusion process, the ability to produce a wide range of snack shapes, and efficient mixing and cooking of ingredients. Additionally, these machines are versatile and can be adapted for different types of snacks and flavor profiles.