Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

Soya chunks machinery refers to the equipment and machines used in the production of soya chunks, also known as soy chunks or textured vegetable protein (TVP). Soya chunks are a popular plant-based protein source made from defatted soy flour. This machine line could make them into various shapes (chunks, flakes, nuggets, grains, and strips) and sizes by different moulds.

Soya chunks machinery refers to the equipment and machines used in the production of soya chunks, also known as soy chunks or textured vegetable protein (TVP). Soya chunks are a popular plant-based protein source made from defatted soy flour. This machine line could make them into various shapes (chunks, flakes, nuggets, grains, and strips) and sizes by different moulds.

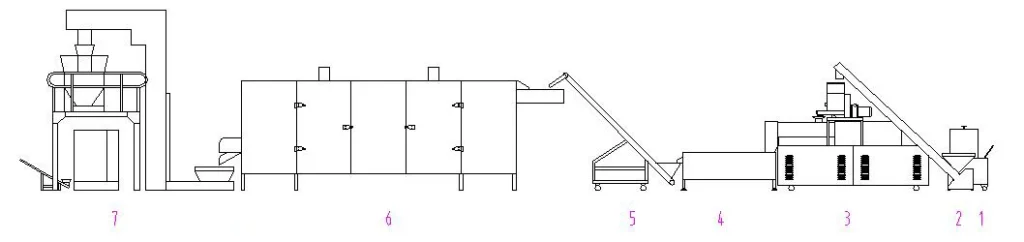

The soya chunks machinery used in the production process typically includes the following key components:

Soybean Cooking/Extrusion: Soybeans meal is cooked and processed through extrusion machines. These machines use heat and pressure to transform the soybean cotyledon into a dough-like substance. The mixture is then passed through a die to create the desired texture and shape of the soya chunks.

Drying: Drying equipment is essential to remove excess moisture from the soya chunks. This typically involves using conveyor dryers, hot air ovens, or other drying methods.

Cooling: After drying, the soya chunks may need to be cooled to room temperature. Cooling machines like conveyors with fans or air cooling systems can be used for this purpose.

Packaging: Packaging machinery is used to weigh, fill, and seal the finished soya chunks into bags or containers for distribution and sale. This may include filling machines, sealing machines, and labeling equipment.

Quality Control: Various quality control machines and equipment may be used throughout the production process to monitor factors like texture, moisture content, and flavor to ensure the final product meets quality standards.

Storage and Handling: Conveyors, bins, and silos may be used for storing raw materials and finished products within the production facility.

Utilities: The production process often requires utilities such as boilers, steam generators, and water treatment systems to provide the necessary heat, steam, and water for cooking and processing.

| Item | AVN 1000 | AVN65 | AVN70 | AVN85 |

| Capacity(kg/h) | 80-100 | 120 | 200 | 500 |