Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

Texturized soy protein (TSP) and textured vegetable protein (TVP) are terms often used interchangeably to describe a product made from defatted soy flour or soy protein isolate. TSP/TVP is a common meat substitute used in vegetarian and vegan dishes due to its high protein content and meat-like texture when rehydrated. A TSP/TVP machine, also known as a soy meat extruder or texturizing machine, is a piece of food processing equipment used to produce these soy-based meat alternatives.

Texturized soy protein (TSP) and textured vegetable protein (TVP) are terms often used interchangeably to describe a product made from defatted soy flour or soy protein isolate. TSP/TVP is a common meat substitute used in vegetarian and vegan dishes due to its high protein content and meat-like texture when rehydrated. A TSP/TVP machine, also known as a soy meat extruder or texturizing machine, is a piece of food processing equipment used to produce these soy-based meat alternatives.

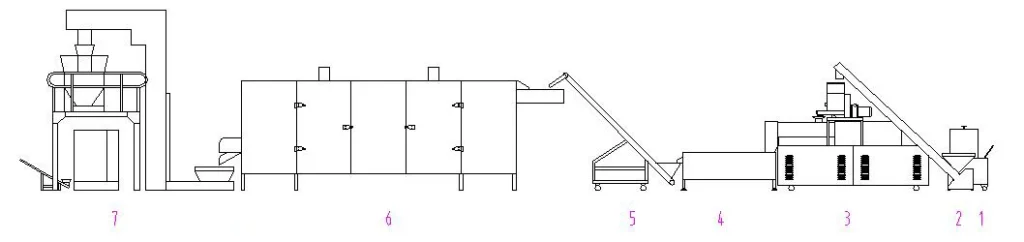

The TSP/TVP texturized soy protein machine machine line working.

Ingredient Preparation: Soybeans are the primary source of soy protein used in TSP/TVP production. The soybeans are cleaned, dehulled, and processed to obtain soy flour or soy protein isolate. This ingredient is rich in protein but has had most of its fat removed.

Mixing: The soy flour or soy protein isolate is mixed with water to create a dough-like mixture.

Extrusion: The dough-like mixture is fed into the TSP/TVP machine’s extruder. Inside the machine, the mixture is subjected to heat, pressure, and mechanical shearing. This process denatures the proteins in the soy and transforms the mixture into a fibrous, meat-like texture. The extrusion process also helps to remove moisture from the mixture.

Texturization: As the mixture is extruded through a die, it takes on the desired shape and texture of meat. Different dies can be used to create various textures, such as minced meat or chunks.

Drying: The extruded TSP/TVP product is often dried to reduce its moisture content. This drying step helps improve shelf life and makes the product suitable for long-term storage. Drying can be done through methods like hot air drying or steam cooking.

Flavoring and Seasoning: After drying, the TSP/TVP can be flavored and seasoned to mimic the taste of real meat. This step often involves adding spices, salt, and other flavoring ingredients.

Packaging: The final TSP/TVP product is packaged for distribution and sale to consumers or food manufacturers.

The soya TSP TVP texturized soy protein machine capacity.

AVN65 machine line has capacity 120-150 kg per hour.

AVN70 machine line has capacity 200-250 kg per hour.

AVN85 machine line has capacity 500-800 kg per hour.

Welcome your inquiry on TSP TVP texturized soy protein machine.

TSP TVP texturized soy protein machine video showing.