Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

Textured Soy Protein (TSP), also known as Textured Vegetable Protein (TVP), is a popular plant-based protein product made from soybeans. TSP is often used as a meat substitute in various food products. The production of TSP typically involves several key processes, and specialized machines are used at each stage of production.

Textured Soy Protein (TSP), also known as Textured Vegetable Protein (TVP), is a popular plant-based protein product made from soybeans. TSP is often used as a meat substitute in various food products. The production of TSP typically involves several key processes, and specialized machines are used at each stage of production.

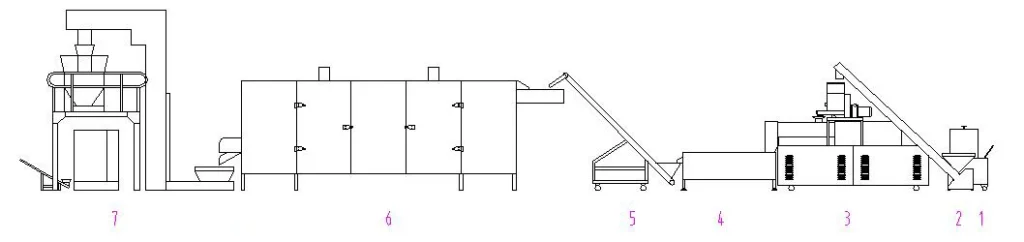

The TSP production process and the machinery involved:

Extrusion: Extrusion is a crucial step in TSP production, where the cooked soybean meal mixture is forced through an extruder. The extruder uses heat, pressure, and mechanical action to convert the soybean mixture into a textured form. The extrusion machine typically includes a feeding system, an extrusion barrel, a die, and a cutting system to produce the desired shapes and sizes of TSP.

Sizing and Shaping: TSP can be further processed to create different sizes and shapes, such as chunks, granules, or strips. Specialized sizing and shaping machines are used for this step.

Drying: After extrusion, the textured soy protein is dried to remove moisture and increase shelf stability. Conveyor dryers or hot air ovens are commonly used for this purpose.

Cooling: The dried TSP may be cooled before further processing or packaging. Cooling equipment such as conveyor systems with cooling fans can be used.

Flavoring and Seasoning: Depending on the final product, TSP may be flavored and seasoned using specialized machines that can coat the TSP with various flavorings, spices, or sauces.

Packaging: Once the TSP is processed and flavored, it is weighed, filled into containers, and sealed using packaging machinery. This machinery may include filling machines, sealing machines, and labeling equipment.

Quality Control: Throughout the production process, quality control equipment may be used to monitor factors like texture, moisture content, and flavor to ensure the final TSP product meets quality standards.

Utilities: Utilities such as boilers, steam generators, and water treatment systems may be necessary to provide the required heat, steam, and water for cooking and processing.

AVN 1000 machine has capacity 80-100 kg per hour.

AVN65 machine line has capacity 120 kg per hour.

AVN70 machine line has capacity 200 kg per hour.

AVN85 machine line has capacity 500 kg per hour.